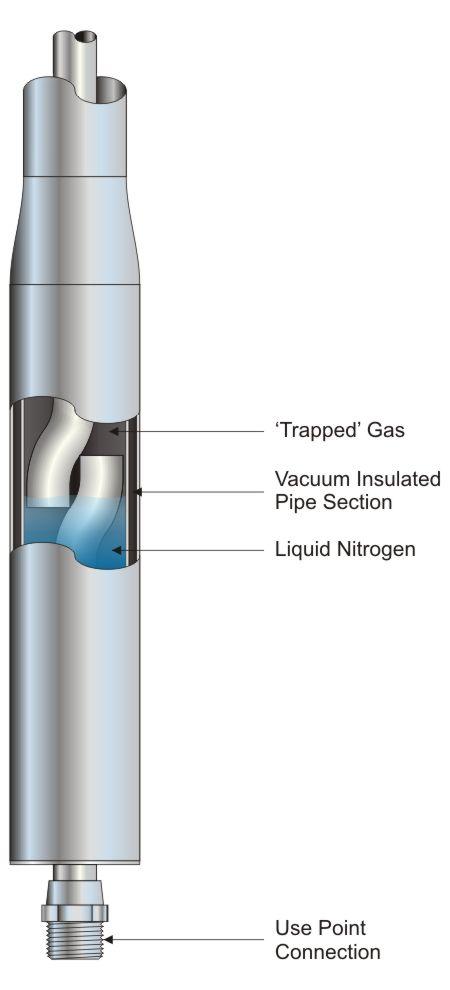

Internal Gas Traps For Cryogenic Systems

Benefits

Reduces Frosting When Equipment Is Not In Use

Internal Gas traps for cryogenic systems are typically installed in vertical drops to liquid nitrogen use points with non-vacuum jacketed terminations. Rated at 150 psi (10 bar) for liquid nitrogen applications.

How It Works

An internal gas trap fills the use point connection with gas instead of liquid nitrogen. The gas trap ‘traps’ a pocket of gas inside the line when the use point or the supply line is shut-off. The gas pocket prevents liquid nitrogen from reaching the non-vacuum jacketed tubing, allowing the connection to defrost when not in use.